A tandem project of Prof. Dr. Dierk Raabe (MPI for Sustainable Materials) and Prof. Dr. Peter Benner (MPI for Dynamics of Complex Technical Systems).

About/Topic

This project pioneers disruptive theory-guided pathways toward circular metals by merging artificial intelligence approaches with complex sustainable metallurgy-related basic scientific challenges. It unites two core research streams: first, the development of AI-guided, microstructure-oriented alloy design to transform mixed post-consumer scrap into high-performance materials; and second, the use of AI-accelerated Fourier Neural Operator solver methods for mesoscopic multiphysics simulations to unravel and optimize the hydrogen-based direct reduction of metal oxides. Together, these approaches build the scientific foundation for a CO₂-free and resource-resilient metal industry.

Persons

- Prof. Dr. Dierk Raabe (Director, Microstructure Physics and Alloy Design Department, MPI for Sustainable Materials)

- Prof. Dr. Peter Benner (Director, Computational Methods in Systems and Control Theory Department, MPI for Dynamics of Complex Technical Systems)

- M. Sc. Soroush Motahari (Max Planck Institute for Sustainable Materials)

- Dr. Yi Hu (Max Planck Institute for Sustainable Materials)

- Dr. Franz Roters (Max Planck Institute for Sustainable Materials)

Project summary

This project pioneers disruptive, theory-guided pathways toward circular metals by merging state-of-the-art artificial intelligence with fundamental challenges in sustainable metallurgy. It targets the scientific transformation of two key bottlenecks in the transition to a net-zero metal industry: scrap-compatible alloy design and hydrogen-based direct reduction.

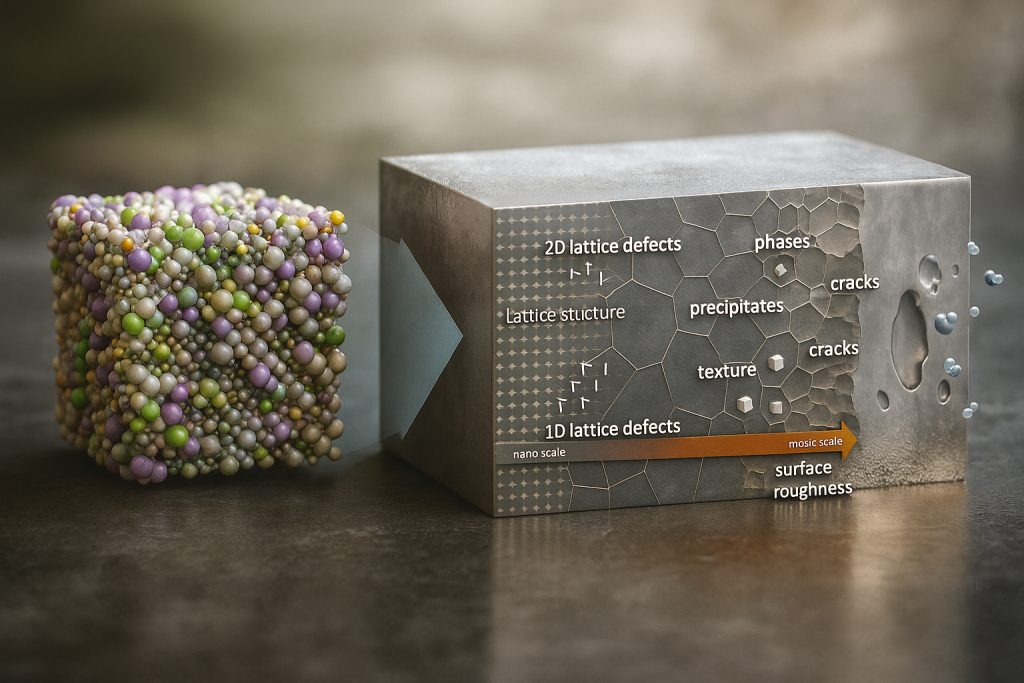

In the first research stream, we develop AI-guided, microstructure-oriented alloy design frameworks capable of extracting structure–property–composition relations directly from complex, mixed post-consumer scrap streams. By integrating graph neural networks, variational autoencoders, and latent-space clustering, the approach enables inverse design of alloys with tailored microstructures and phase stability, even under non-ideal impurity profiles. This allows for the upcycling of heterogeneous scrap into high-performance structural and functional materials, overcoming long-standing barriers in secondary metallurgy and compositional uncertainty.

The second research stream advances AI-accelerated mesoscopic multiphysics simulations for the hydrogen-based direct reduction (HyDR) of iron, nickel, and other metal oxides. Using Fourier Neural Operator (FNO) solvers, we learn the spatio-temporal evolution of microstructural fields, including phase transformation, porosity coarsening, and gas–solid mass transport. This approach drastically reduces computational costs compared to conventional finite element or phase-field models while retaining physical fidelity. The resulting digital twin of HyDR kinetics enables the optimization of reactor conditions, particle morphologies, and reduction pathways under dynamic H₂/H₂O gas compositions.

Together, these two AI-driven research pillars establish a rigorous scientific foundation for a CO₂-free, circular, and resource-resilient metal industry, uniting data-driven alloy design with accelerated green process modeling.